Tool storage encompasses a variety of systems designed to organize, protect, and provide easy access to tools in workshops, garages, or professional settings. Effective tool storage enhances efficiency, prevents damage, and promotes safety by reducing clutter. In 2025, options range from portable solutions for on-the-go use to stationary units for high-volume organization. This guide outlines the primary types of tool storage, their features, applications, and considerations, helping you select the most suitable system for your needs.

Primary Types of Tool Storage

The following categories represent the most common types of tool storage, each tailored to specific use cases and environments:

- Portable Tool Boxes: Compact, handheld containers with compartments for small tools and accessories, often made from plastic or metal for durability. They typically hold 10-50 tools and are ideal for job sites or home DIY projects. Advantages include portability and affordability; limitations involve limited capacity for larger tools.

- Tool Chests: Multi-drawer units, usually stacked on top of rolling cabinets, providing organized storage for hand tools, fasteners, and small parts. They offer 5-10 drawers with capacities of 50-200 pounds each. Best for mechanics or workshops needing quick access; pros include secure locking, but they require a stable base.

- Rolling Tool Cabinets: Mobile cabinets on casters with multiple drawers for heavy-duty storage, supporting 500-2,500 pounds total. Suitable for garages or professional environments; advantages are mobility and high capacity, though they occupy floor space.

- Stationary Tool Cabinets: Fixed, wall-mounted or freestanding cabinets for permanent storage, often with locks and shelves for larger tools. They hold 1,000-3,000 pounds and are ideal for organized workshops; pros include stability, but lack portability.

- Truck Tool Boxes: Weatherproof boxes mounted in truck beds for transporting tools, made from aluminum or steel with capacities of 200-500 pounds. Best for contractors; advantages are security and weather resistance, but limited to vehicle use.

- Modular Tool Boxes: Stackable or connectable units allowing customization, often with drawers and compartments for 100-300 tools. Ideal for evolving workspaces; pros include flexibility, though assembly can be complex.

- Tool Carts: Wheeled carts with trays or drawers for on-the-move organization, holding 200-500 pounds of tools. Suitable for mechanics; advantages are accessibility, but lower capacity than cabinets.

- Drawer Organizers: Inserts or trays for dividing drawers, used within cabinets to separate small tools or fasteners. Best for precision organization; pros include customization, but require existing storage.

- Magnetic Tool Holders: Strips or bars with magnets for holding metal tools like wrenches or screwdrivers on walls or cabinet doors. Ideal for quick access; advantages are space-saving, though limited to magnetic items.

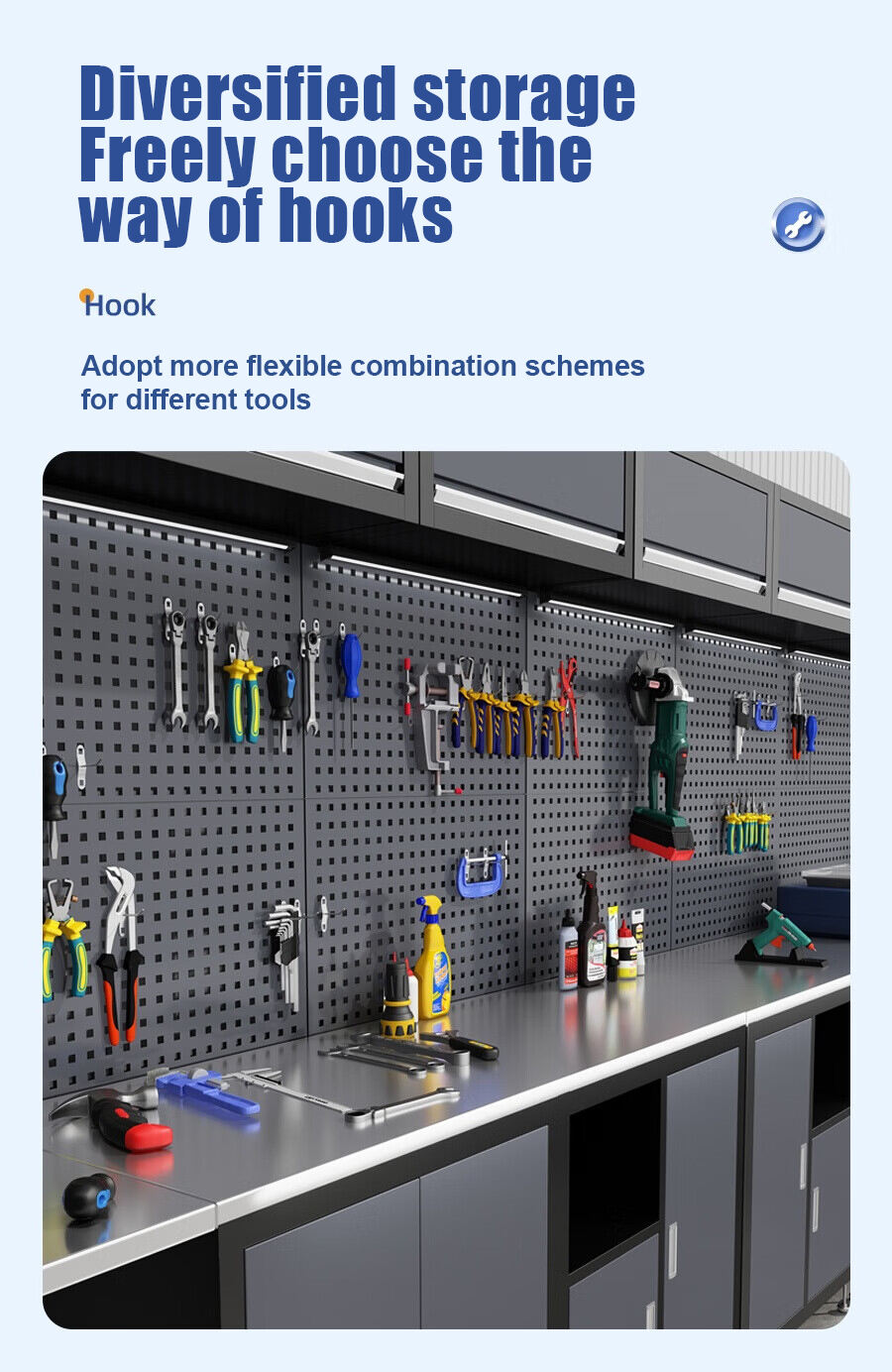

- Tool Racks and Rails: Wall-mounted racks or rails with hooks for hanging tools, supporting 50-200 pounds. Best for garages; pros include visibility, but require wall space.

- Socket Trays and Rails: Specialized holders for sockets and bits, often magnetic or foam-based, used in drawers or on benches. Ideal for mechanics; advantages are precise organization, though tool-specific.

- Hanging Accessories (Bins, Baskets, Hooks): Add-ons for walls or pegboards to store small parts or tools. Best for customizable storage; pros include flexibility, but dependent on mounting surfaces.

Comparison Table of Tool Storage Types

| Type | Capacity (Typical) | Mobility | Best For | Material Options |

|---|---|---|---|---|

| Portable Tool Boxes | 10-50 tools | High | Job Sites | Plastic, Metal |

| Tool Chests | 100-300 tools | Low | Workshops | Steel |

| Rolling Tool Cabinets | 500-2,500 lbs | High | Garages | Steel |

| Stationary Tool Cabinets | 1,000-3,000 lbs | Low | Permanent Storage | Steel |

| Truck Tool Boxes | 200-500 lbs | High (Vehicle) | Contractors | Aluminum, Steel |

| Modular Tool Boxes | 100-300 tools | Medium | Evolving Workspaces | Plastic, Metal |

| Tool Carts | 200-500 lbs | High | Mechanics | Steel |

| Drawer Organizers | Small Items | Low | Precision Storage | Foam, Plastic |

| Magnetic Tool Holders | 10-20 tools | Low | Quick Access | Magnetic Steel |

| Tool Racks/Rails | 50-200 lbs | Low | Garages | Metal |

| Socket Trays/Rails | Socket Sets | Low | Mechanics | Plastic, Metal |

| Hanging Accessories | Small Parts | Low | Customizable Storage | Plastic, Metal |

How to Choose the Right Tool Storage Type

Select based on your workflow:

- For mobility: Portable tool boxes or rolling cabinets.

- For high capacity: Stationary cabinets or modular systems.

- For small items: Drawer organizers or magnetic holders.

- Consider environment: Metal for durability in garages; plastic for lightweight portability.

Tips for Effective Tool Storage

To get the most out of your tool storage:

- Label Everything: Use tags or dividers for quick identification.

- Prioritize Accessibility: Store frequently used tools at eye level.

- Maintain Regularly: Clean and inspect storage units quarterly to prevent rust or wear.

- Combine Types: Use tool chests with magnetic holders for comprehensive organization.

Conclusion

Understanding the different types of tool storage—from portable boxes to modular cabinets—allows for tailored solutions that enhance productivity and protect investments. By matching the type to your specific needs, such as mobility or capacity, you can create an efficient workspace. For durable metal-based tool storage, consider Pulage Furniture's heavy-duty cabinets, designed for workshops and garages with secure locking and high-capacity drawers to keep your tools organized and accessible.